CNC MACHINING, PROTOTYPING & SMALL BATCH PRODUCTION

Under one roof in our Hertfordshire workshop, we help teams move from prototype to pre production and batch supply with CNC machining, laser cutting and marking.

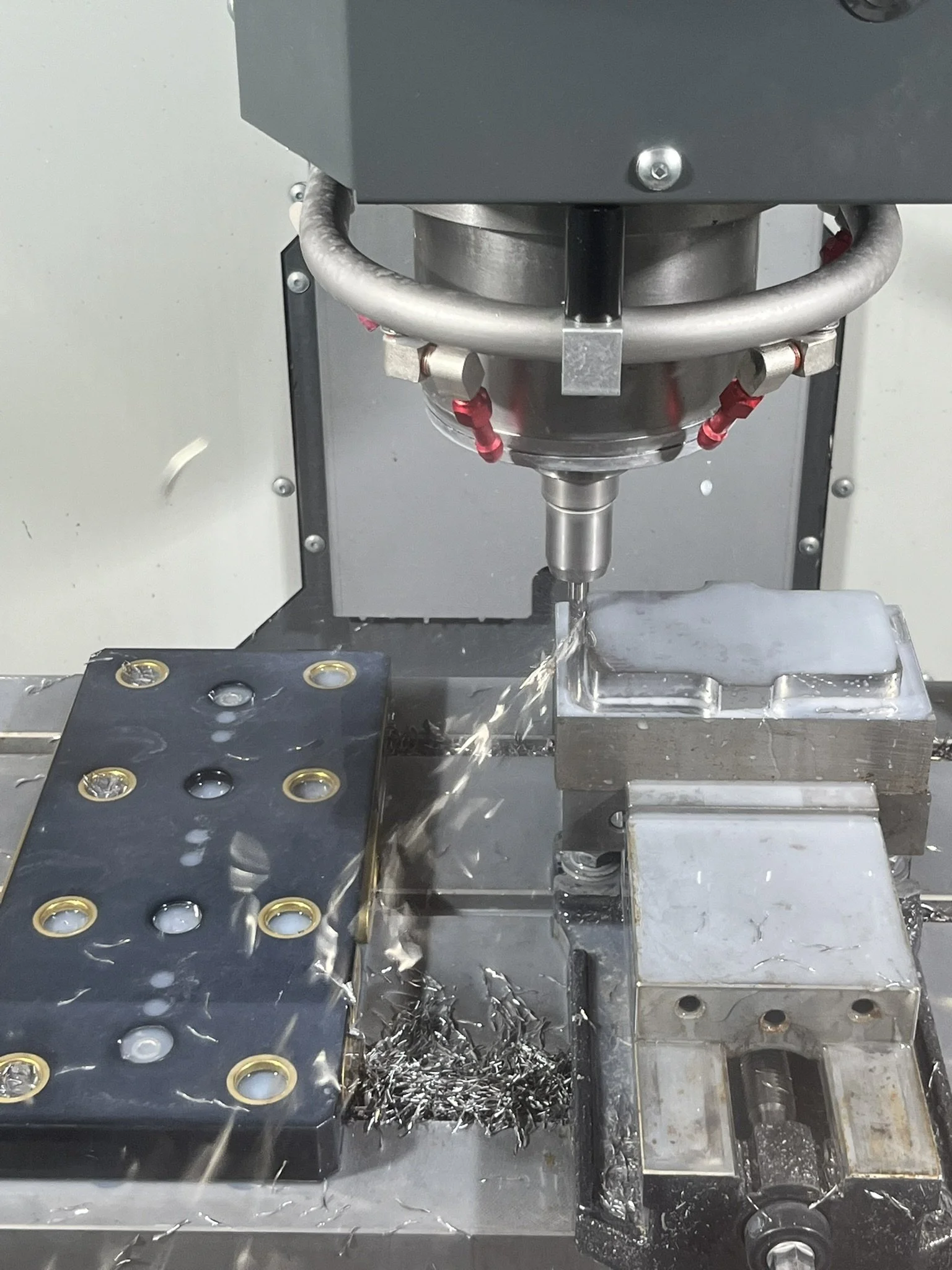

We specialise in CNC machining and in house manufacturing, continually investing in modern equipment to deliver consistent, high quality components.

We work closely with UK manufacturers, product designers and engineers. Acting as an extension of your team, from prototype through to pre production and batch supply.

Watch our video to see how we combine capability, flexibility and personal service to keep your projects moving.

CAPABILITIES UNDER ONE ROOF

We bring machining, laser and prototyping together under one roof to support designers, engineers and product teams from prototype through to batch supply.

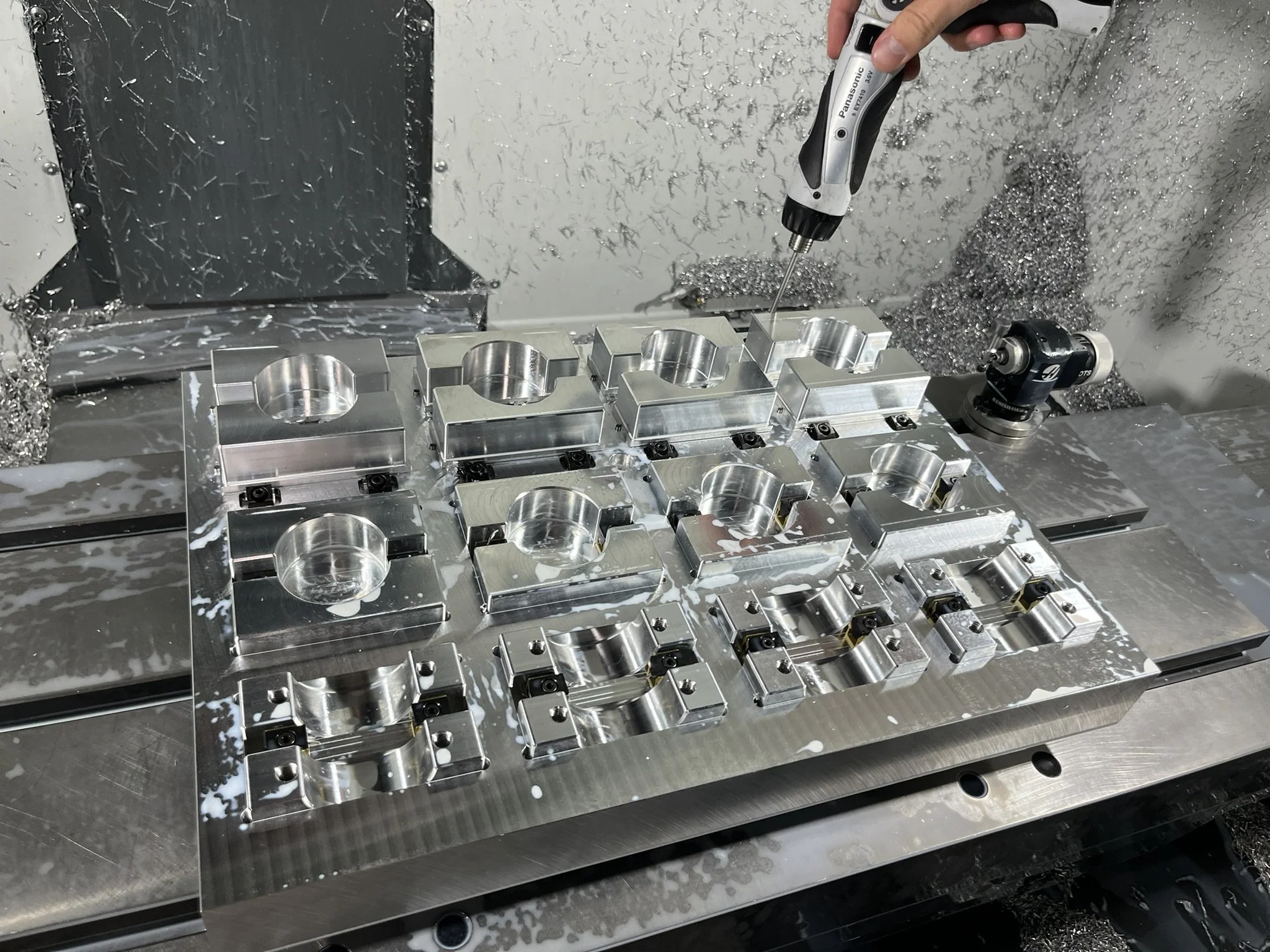

Aluminium, stainless steel, brass and engineering plastics machined for housings, heatsinks, brackets and hardware. Supports prototypes, pre-production and batch supply.

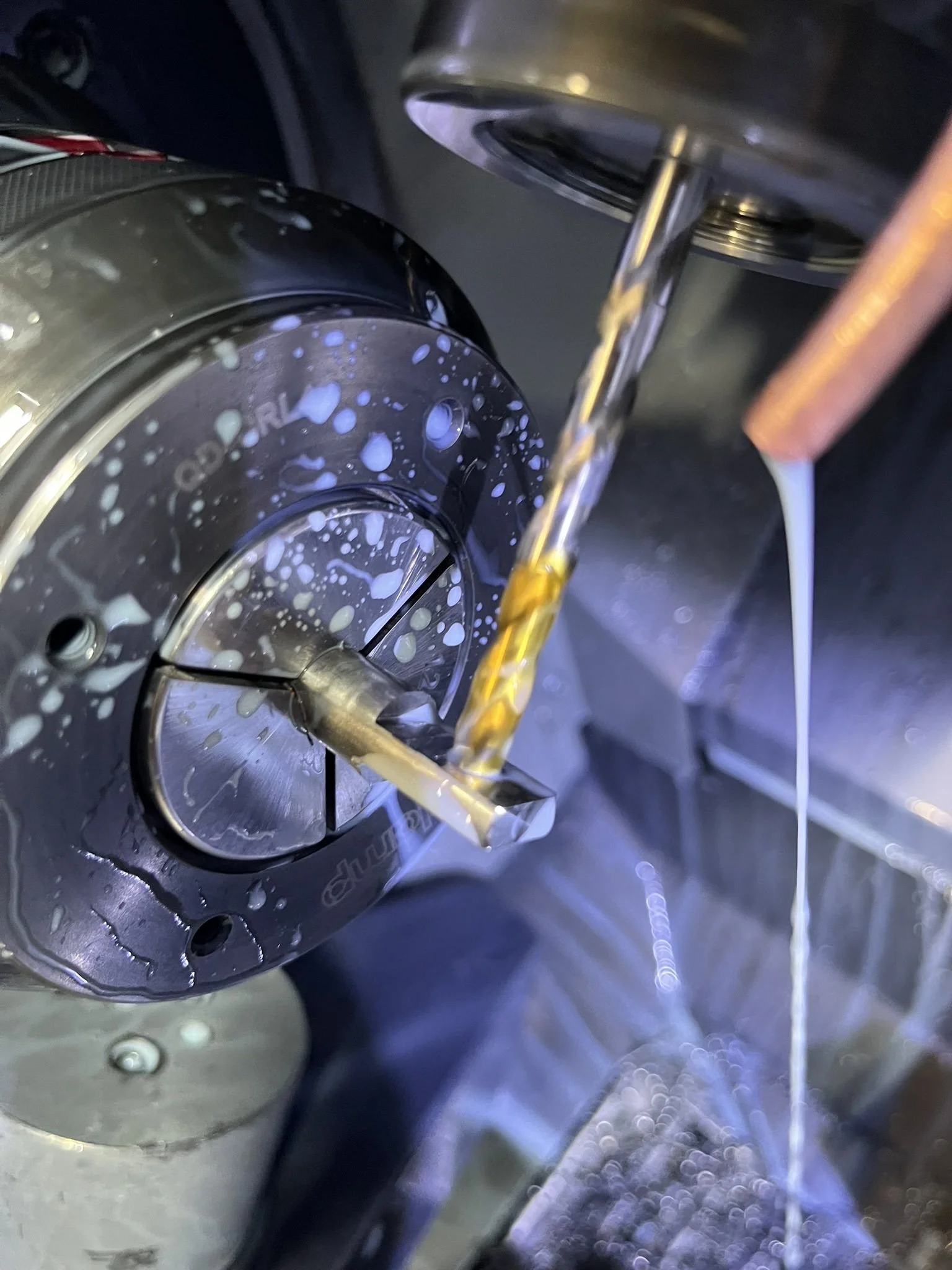

Turned components with Y-axis milling for features, threads and mounting details in aluminium, stainless and brass. Ideal for lighting, hardware and electro mechanical builds from prototype to pilot supply.

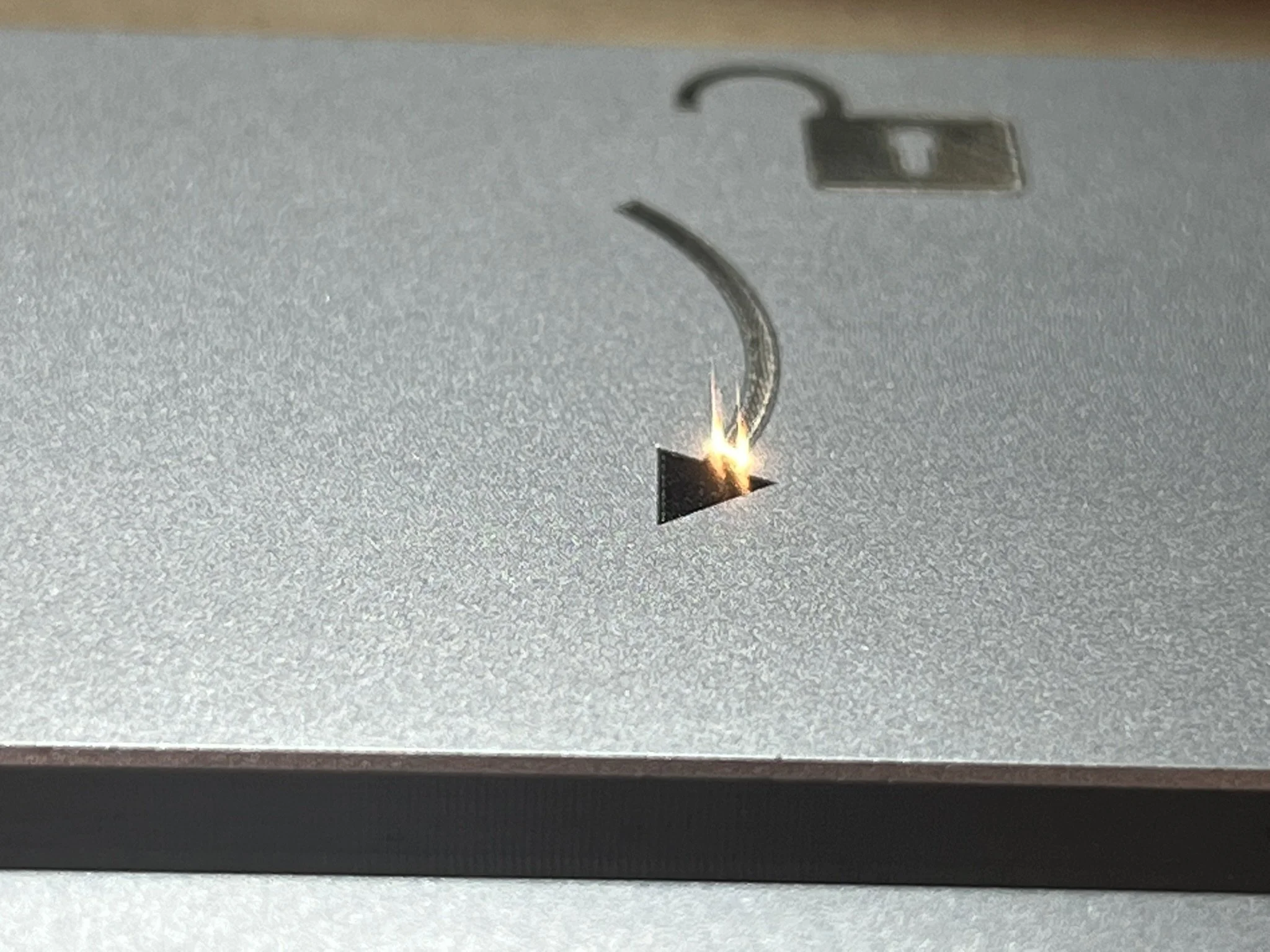

Laser cut plastics and optical panels for enclosures, diffusers and sample packaging inserts. Fast iteration for development and small batch.

Batch and prototype marking for identification, traceability and branding. Suited to pilot runs, sample kits and R&D assemblies.

Machined lighting hardware, housings and heatsinks with optional LED integration. Serving architectural, horticultural and commercial lighting projects.

CNC machined prototypes, sample builds and pre production assemblies supporting validation before batch manufacture.

HOW WE MAKE PARTS

All imagery on our website shows genuine work produced in our Hertfordshire workshop. From prototyping through batch supply. No stock photos, just real machining, laser work and assembly.

THE KARPAS DIFFERENCE

We help engineers, designers and product teams get parts made quickly and reliably, with CNC machining, laser services and prototyping all under one roof.

From one off prototypes to repeat batches, we focus on communication, flexibility and building long term partnerships.

-

Send us your drawing or CAD file (STEP, PDF or DXF) and we’ll review it, ask any questions and come back with pricing and next steps.

If you’re earlier in the process, we can help refine designs for machining or prototyping. -

Yes, we make one off prototypes, sample builds and repeat batches. Many customers start with prototypes and later move into pre production and supply.

-

Timelines depend on complexity and quantities. Prototype and sample builds are generally faster; production batches can be scheduled. If you have a deadline, just let us know.

-

You’ll speak directly with the engineering team machining your parts, no account managers, no barriers. Communication is quicker and iteration is easier.

-

We machine in house in Hertfordshire and ship UK wide. Customers are welcome to collect if preferred.

-

Karpas Engineering is a CNC workshop in Hertfordshire supporting UK product teams, designers and manufacturers with machining, laser services and prototyping. We focus on fast iteration, consistent quality and clear communication, the things that make development and production smoother.

We don’t overpromise. We make good work, help improve designs and keep things moving.

We prioritise local sourcing, sustainable practices and long term partnerships. Capability matters, but service and reliability matter even more.

Wireless file transfer for older CNC machines, without USB swaps. Helps keep programming fast and legacy equipment productive.

WHO WE WORK WITH

Engineers & product teams

Hardware and electro mechanical products

Lighting manufacturers & OEM

R&D and prototyping

Sample & pre production builds

Small batch & repeat supply

Legacy CNC workflows

READY TO GET PARTS MADE?

Send us your drawing or CAD file and we’ll review it, ask any questions, and come back to you with next steps.